- Refrigerator product type

- Agricultural subsidies

- Zk-100 fruit and vegetable fresh-keeping

- Zk-150 fruit and vegetable fresh-keeping

- Zk-300 fruit and vegetable fresh-keeping

- Zk-400 fruit and vegetable fresh-keeping

- Zk-500 fruit and vegetable fresh-keeping

- Zk-800 fruit and vegetable fresh-keeping

- ZK-YC-10 fruit and vegetable cooling machines

- Main cold storage products

- Cold storage room

- Freezing cold

- Refrigerated cold storage

- Dual temperature refrigerator

- Cold storage logistics

- Explosion-proof refrigerator

- Food storage

- Controlled atmosphere cold storage

- Wine refrigerator

- Mushroom cold storage

- Purify the medicine cold storage

- Other equipment

- Refrigeration components

- Refrigeration accessory

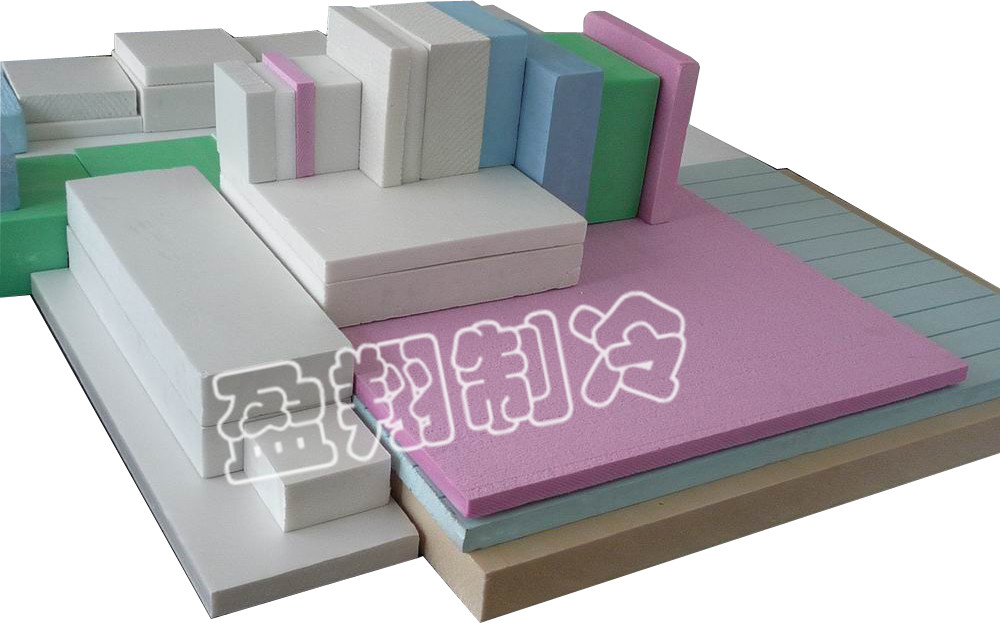

Plastic extrusion Panel

Performance characteristics of extrusion-plastic extrusion Panel

1, excellent thermal insulation properties

With high thermal resistance and low linear expansion ratio of the low, the structureof closed-cell rate is above the 99%, forming a vacuum to avoid air flow cooling to ensure its thermal insulation properties of a lasting and stable, relative to the rate of the obturator of polyurethane foam 80%, lead speaks for itself. Proves 20mm XPS extruded thermal insulation boards, 50mm thick polystyrene insulation effect, 120mm thick cement perlite. Therefore, this material is the best choice for building insulation.

2, excellent strength resistance

Due to the special structure of XPS plate, its very high compressive strength, excellent impact resistance, depending on the type and thickness of the compressive strength of XPS to more than 150~500Kpa, able to withstand the system load, widely used in geothermal projects, highways, airport runways, square ground, large and decorative areas such as thermal insulation of cold storage.

3, excellent water repellency, moisture-proof

Water absorption is an important parameter for measuring insulation. After absorbing water insulation materials thermal insulation performance goes down, cold cases, inhaled water can easily freeze, undermines the structure of thermal insulation material, so that the sheet resistance and insulation performance. Because polystyrenemolecular structure itself does not absorb water, plate stable molecular structure and gapless, solve other material problems such as water leakage, seepage, Frost andcondensation.

4, light texture, easy to use

XPS Board fully closed-cell foam structure with honeycomb structure, so that it has the characteristics of light weight, high strength, easy to cut, transport, and difficult to damage, easy to install.

5, good stability, corrosion protection

Long time of using in the, not aging, and not decomposition, and not produced harmful material, its chemical performance extremely stable, not for sucking water and corrosion, led to degradation, makes its performance declined, in high temperature environment Xia still can keep its superior of performance, according to about information introduced, XPS squeeze plastic insulation board even using 30-40 years, still can keep excellent of performance, and not occurred decomposition or mildew, no toxic material of volatile.

6, product environmental performance

XPS Board tested by the relevant departments of the State chemical stability, without harmful volatile organic compounds, is harmless to human body, producing raw materials used environmentally friendly materials, without any industrial pollution. Theproduct is environmentally friendly building materials.

Plastic extrusion Panel-scope

Roof thermal insulation wall insulation, steel roofing, building, buildings, ground moisture, square ground, floor heave control and air-conditioning ventilation ducts, insulated layer of the runway of the airport, high speed railway subgrade

Keywords: